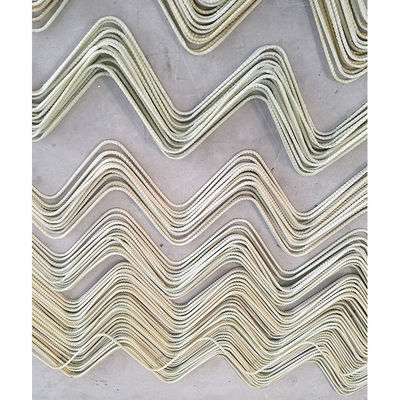

1. High tensile strength. -Its strength is approximately double of steel bar, And when you bend it, it will bounces back quickly, that make the building more stable.

-Fiberglass rebar is waterproof and resistant to seawater corrosion, it never rust even stay in the concrete or building wall for many many years.

3. Low density and light weight.

-The meter weight is only 1/4 of steel bar, the worker can carry it easily, And also the transportation cost can be reduced much more.

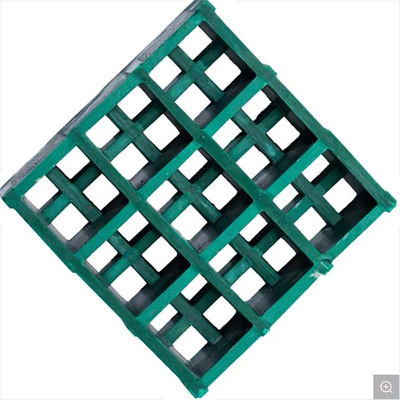

4. Insulation, No static.

-It has no electrical conductivity, and no sparks will be produced when being cut, it's particularly suitable for high risk gas zones; like Coal mines, oil fields.

5. Easy Cutting.

-Easy to cut, very suitable for construction of tunnels and subway projects, It avoids damages to cutter heads and does not delay excavation.

Applications: Сonstruction, subway tunnel, coal mine tunnel, rock surface anchoring, sea wall, parking structures, slope support, transportation industry and dam etc.